Precision Planting is a leading provider of agriculture technologies for farmers who Believe in Better™ with a focus on creating solutions for current agronomic issues and providing practical educational resources. Precision Planting products upgrade a farmer’s existing planter, air seeder, drill, sprayer, liquid fertilizer applicator, dry fertilizer applicator, and combine to maximize the performance of their equipment. Precision Planting provides precision ag solutions for every season. |

From retrofit planter components like vSet®, DeltaForce®, and SpeedTube®, to cutting-edge technologies such as SmartFirmer® and 360° FieldView™ compatibility, Precision Planting provides tools that enable growers to make real-time, in-field decisions with confidence. These solutions enhance seed placement accuracy, optimize downforce, and ensure consistent emergence—key factors in driving yield potential.

Retrofit the equipment you already own to maximize its benefit to your farm. Precision Planting is part of PTx, the leading precision agriculture brand of AGCO, offering solutions for every season and every pass, no matter the color of equipment. .

Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.

20|20 – Monitoring

The 20/20 precision product is ideal for monitoring in the field. If you can’t see it, you can’t change it. The 20|20 system informs your farming decisions by monitoring, controlling, and diagnosing field conditions and equipment.

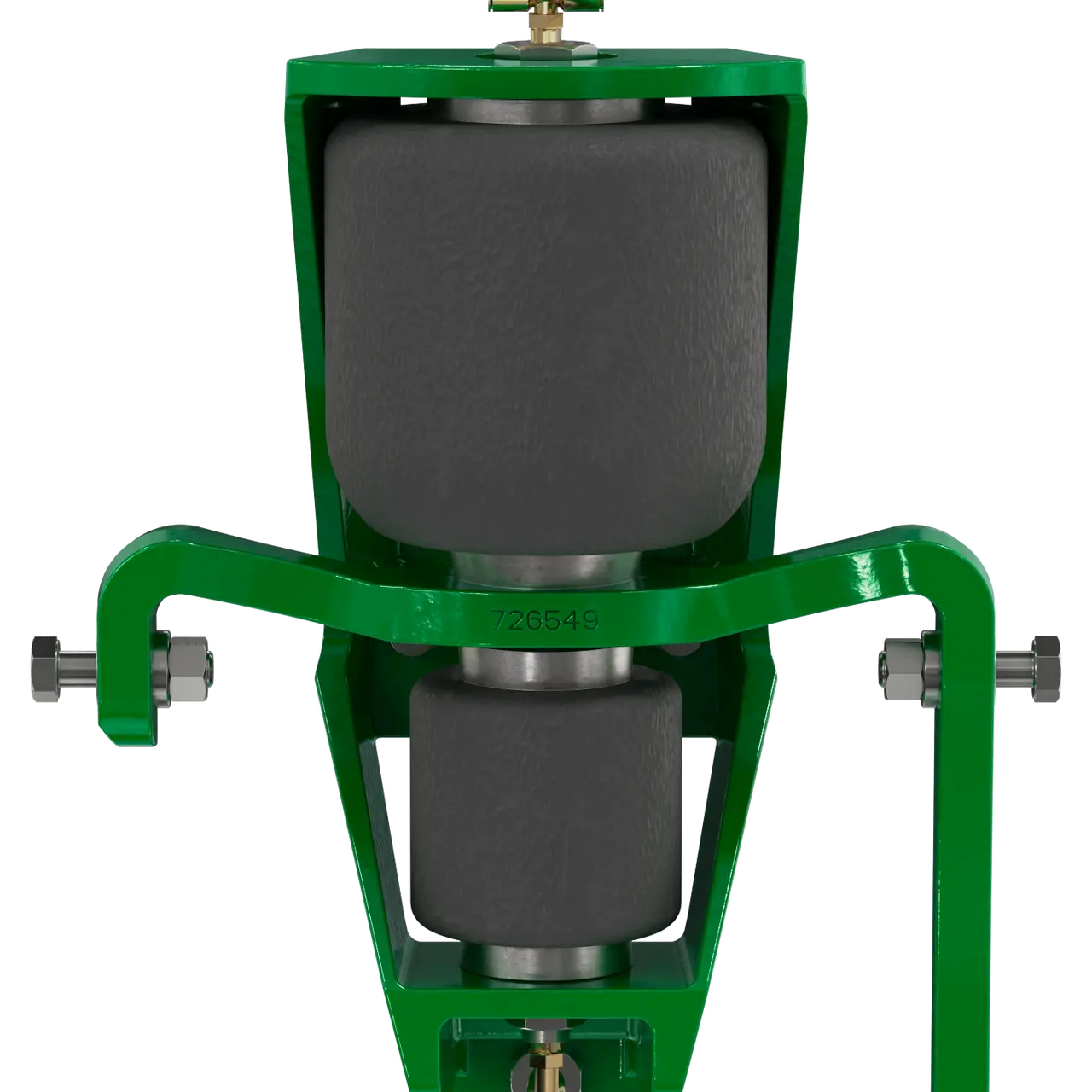

FurrowForce

Setting your closing system correctly is tough. FurrowForce is a two-stage closing system that adapts to your planting conditions to remove air pockets and firm soil to retain moisture, giving you confidence that your crops will germinate the best that they can.

FurrowForce is a 2-stage closing system. In the first stage, notched wheels work to close the seed furrow from the bottom up, fracturing to eliminate air pockets, even in extreme no-till conditions where traditional closing systems struggle. In the second stage, stitch wheels carry weight on them to firm the soil. This consistent firming is especially beneficial behind spring tillage where the seed environment is at risk of drying out.

SmartDepth

Adjusting depth on your planter is time-consuming. SmartDepth allows you to quickly and easily make depth adjustments, from inside the cab, as conditions change. This saves you time and gives you the confidence that each row is set right where you need it to be.

AirForce

A single downforce setting across the entire field leads to too much downforce in some areas and too little in others, causing yield loss. AirForce is a downforce control system that measures variability in the field and automatically adjusts your downforce planter-wide, or by section, according to changing field environments, so you stop sacrificing yield. AirForce measures and adjusts downforce through the planter’s airbags. It works on planters with down and lift bags, down-only bags, and lift-only bags. It operates as either planter-wide or a two-section control mode.

DuraWear

You can’t run your planter without the basic components. But you can equip your planter with durable wear parts from Precision Planting. Equip your planter with components built to last:

DuraWear™ Depth Handle

DuraWear™ Parallel Arms

- DuraWear™ Gauge Wheel Arms

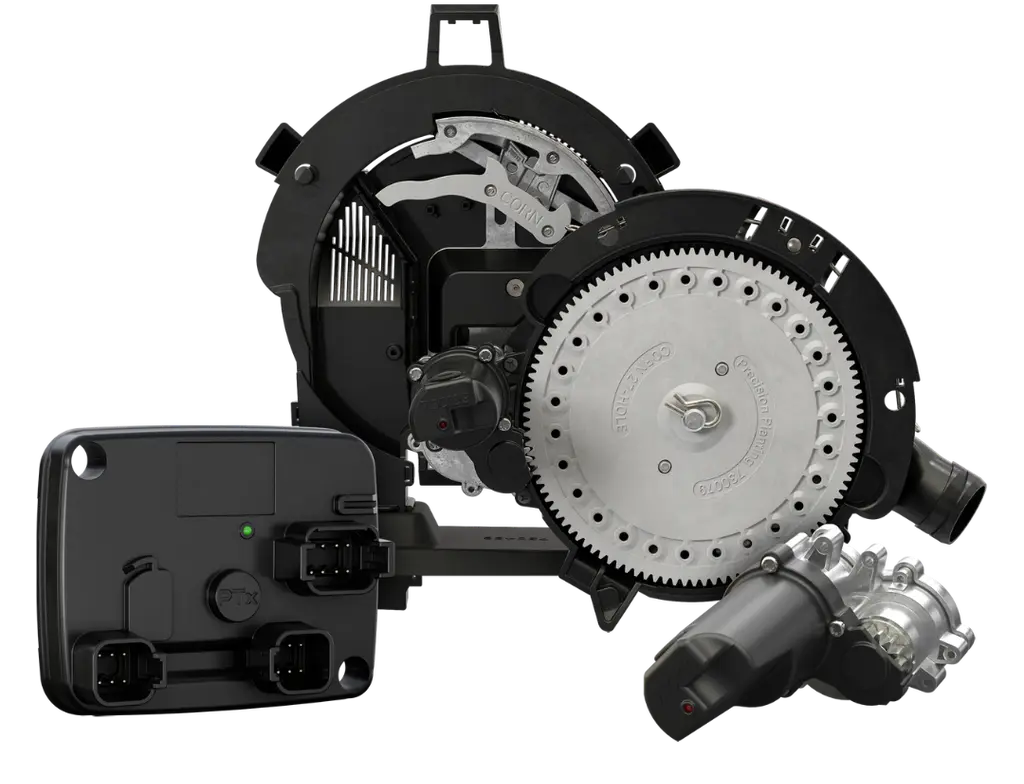

DeltaForce

Running a single downforce setting across an entire field causes yield loss because the setting is rarely correct. DeltaForce is an automated row-by-row downforce control system that measures and adjusts downforce every time there is variability in your field, so your crops will thrive for optimal yields.

ReadyRowUnit

Don't trade planters—upgrade what you already own

Buying new planters is expensive and usually the row units and technology are the only things that need to be upgraded. The Precision Planting Ready Row Unit is a solution that allows you to keep your existing planter frame, but upgrade to new row units and technology, for a fraction of the cost of a new planter. You’ll have the planter that you want and save a ton of money. Learn More

CleanSweep

Setting row cleaners correctly is time-consuming and frustrating. CleanSweep allows you to make row cleaner adjustments from the cab, eliminating the frustration of getting row cleaners set, saving you time while planting. CleanSweep air cylinders can be added to your existing row cleaners to adjust down pressure from the cab, adding further control for a lower cost. Since it is easy, you will make adjustments when you should and prevent:

• Late emergence from heat and moisture loss

• Seedling diseases

• Nutrients tied up by residue

Reveal

Row unit-mounted row cleaners hurt row-unit ride and affect downforce requirements. Reveal is frame-mounted, removing its impact on the row-unit. With its own internal gauge wheel and treader wheels, Reveal precisely controls the depth of the cleaning tines to create a consistently clean and ideal seeding environment for even emergence to occur. Learn More

eSet

John Deere vacuum meters need adjustment to properly singulate seeds, resulting in skips and multiples. The eSet meter is a retrofit system that goes inside of a John Deere vacuum meter and uses a flat disk without cells, paired with a floating singulator that doesn't need adjustments. Simply set your vacuum, fill the planter with seed, and go.

mSet

Typical planters do not allow an on-the-go hybrid change, which doesn’t let you match hybrid to the field environment. mSet is a multi-hybrid planting system that allows you to plant two hybrids using a divided hopper with one vSet meter. mSet also works with SpeedTube for high-speed multi-hybrid planting.

The mSet system, along with its vSet companion, can be utilized with both seed tubes and SpeedTube. The choice is yours - maximize the potential of each area of the field at a traditional speed, or maximize genetics and efficiency by pairing multi-hybrid planting with high-speed planting.

Precision Meter

The performance of finger meters vary when planting a range of seed sizes and shapes, leading to skips, multiples, and lost yield. PrecisionMeter uses an adjustable brush to better singulate a range of seed sizes and shapes. When planting with PrecisionMeters from Precision Planting, you can have confidence in your singulation performance.

SwathModule

Overapplication of seed and fertilizer in the field can cost you unnecessary money. The Precision Planting swath module shuts off sections of your machine to reduce overlap, lowering your input costs.

vConnect™ | Drive

If you’re not satisfied with your mechanical drive or current metering system, vConnect | Drive allows you to upgrade to vDrive electric motors and vSet seed meters for industry-leading singulation, rate control and individual row control – all through an ISOBUS display, so you can plug and plant with confidence.

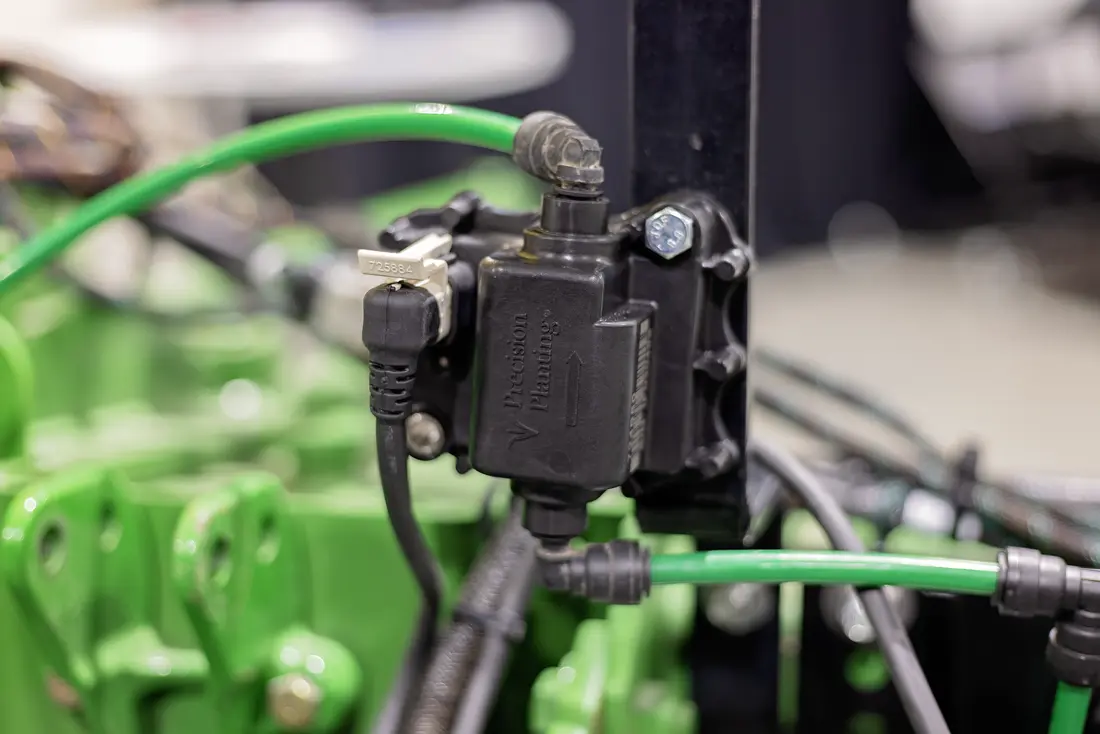

RowFlow ®

Clutch and hydraulic drive control

RowFlow is a simple-to-use system to take command of swath control, prevent overlap, save seed, and plant variable rates with ease, saving you time and eliminating frustration while improving your yield.

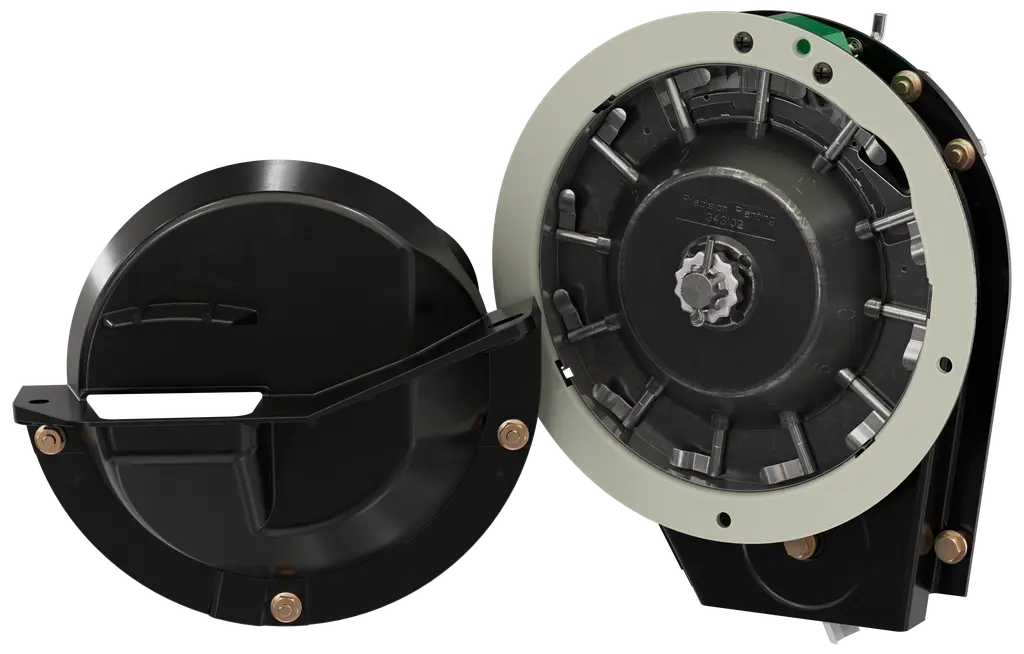

vSet ®

Effortless meter accuracy

Traditional seed meters need continual adjustment to plant accurately which leads to skips, doubles, and ultimately, lost yield. vSet seed meters singulate seeds accurately without any adjustments resulting in perfect seed placement throughout your field.

vSet ® Select

Dual meter multi-hybrid

Typical planters only allow you to plant one seed hybrid at a time, which doesn’t allow you to match hybrid to the field environment. vSet Select is a multi-hybrid planting system that allows you to plant two hybrids using dual meters for instantaneous switching between hybrids.

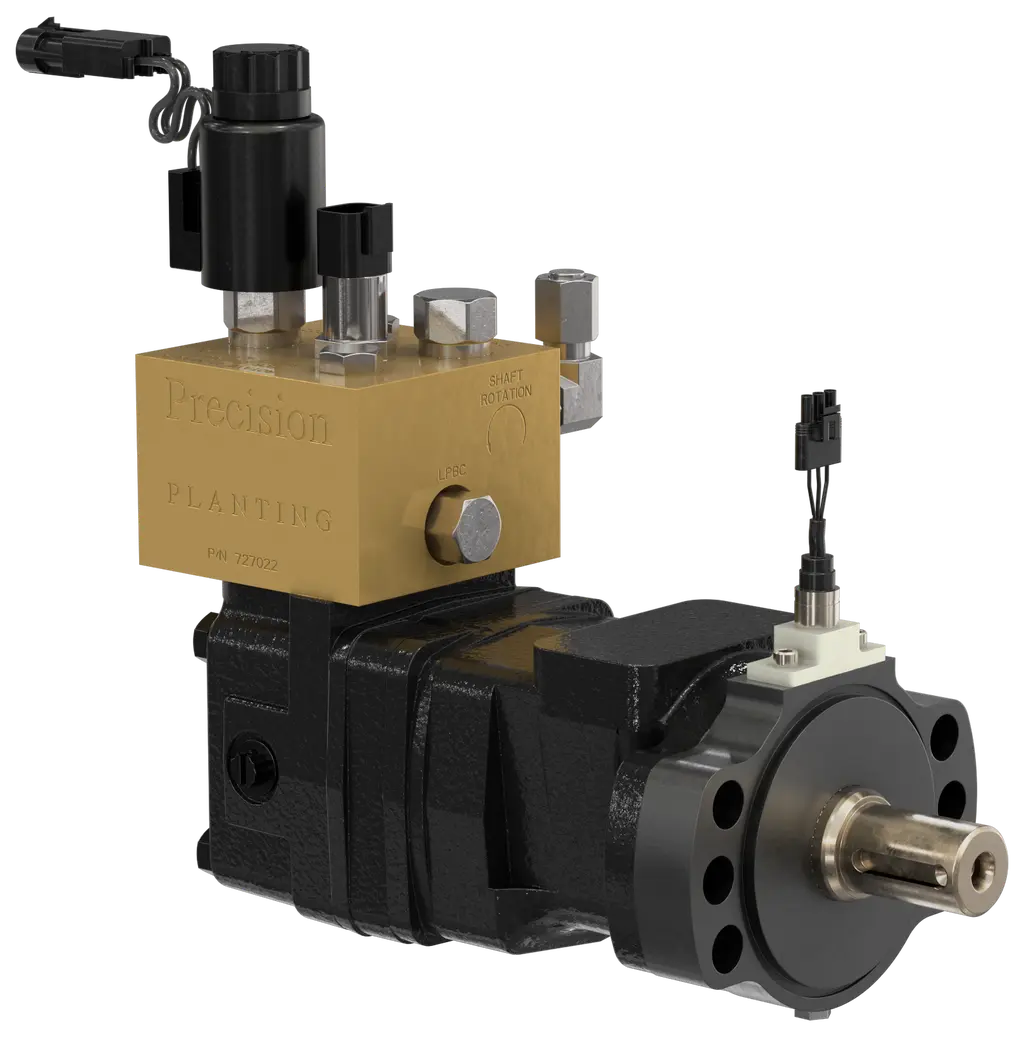

vDrive ®

Maintenance-free electric drive system

Mechanical drive systems require costly and time-consuming maintenance. vDrive is a maintenance-free electric drive system that lets you breeze through planting without the headaches of a mechanical drive system.

BullsEye®

Longer seed tube life, better spacing

Traditional seed tubes create erratic seed spacing due to premature wear and the sensor location. BullsEye seed tubes have tungsten carbide tips that make the seed tube last longer and a recessed sensor eye to prevent inconsistent seed spacing, eliminating the frustration of finding out your stand is not all that you expected when it emerges.

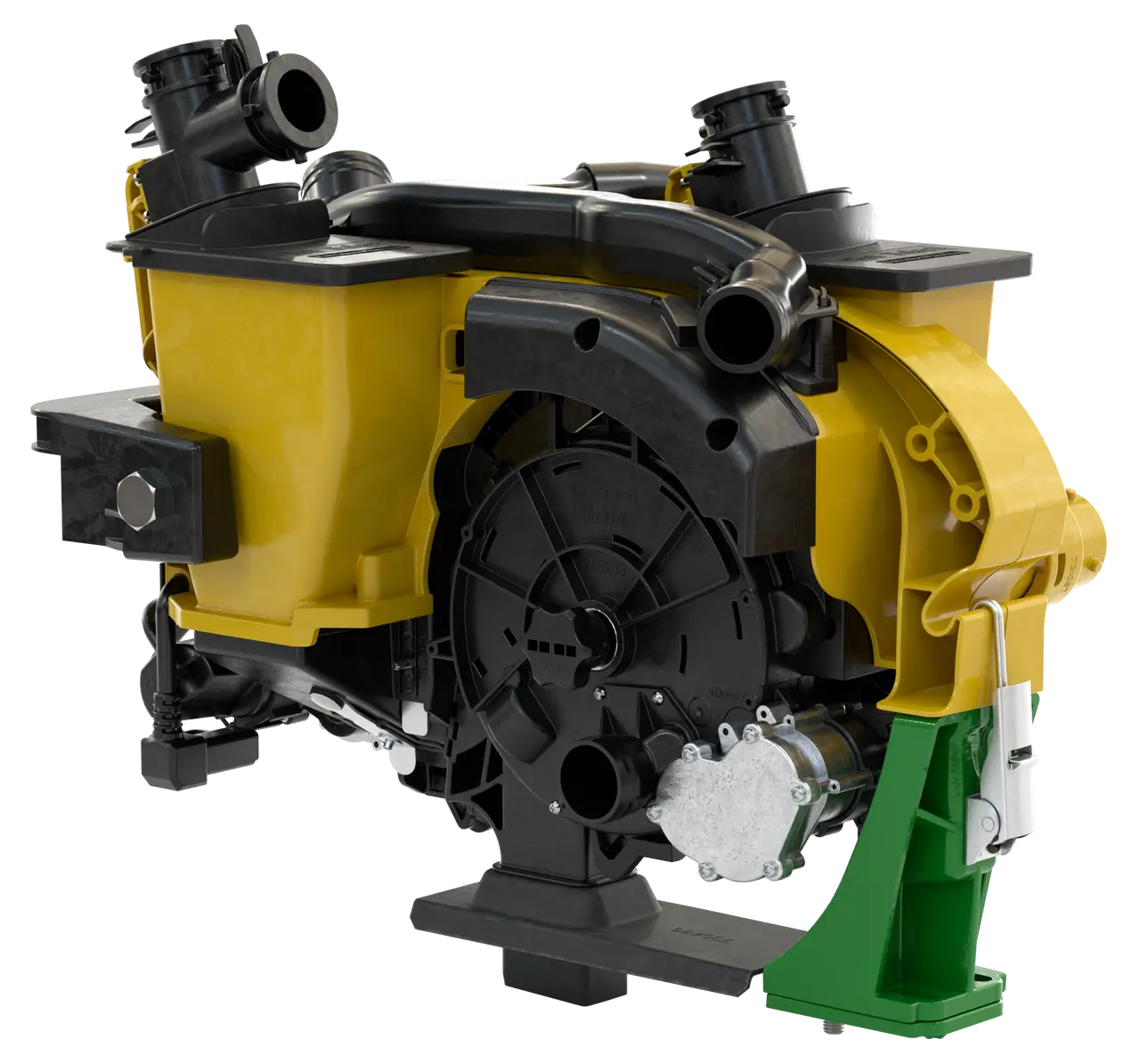

SpeedTube®

High-speed seed delivery system

Most planting seasons have weather challenges that make it difficult to plant all your fields in ideal conditions. SpeedTube is a seed delivery system that allows you to double your planting speed without sacrificing performance. You’ll have a sense of accomplishment when the rain comes and your planter is already back in the shed.

WaveVision®

See seeds, not dust

Traditional seed sensors count dust and seed, giving you inaccurate population counts and that uneasy feeling of not knowing if you can believe your planter monitor. WaveVision is a seed sensor that counts only seeds and not dust, giving you confidence that the population you see on your monitor is the population that you’re planting.

Keeton®

Ensure seed to soil contact

When seeds don't make it to the bottom of the furrow, there is an air gap that causes a delay in emergence. Seed Firmers press each seed to the bottom of the furrow to improve seed-to-soil contact and give you a crop stand you can be proud of.

SmartFirmer®

See inside the soil

Digging a few seeds per field doesn’t give you a complete picture of whether your depth setting is correct. SmartFirmer is a seed firmer-sensor that measures the amount of moisture available to the seed, organic matter, and temperature, so you can adjust your depth correctly and know you will have a consistent crop stand.

EMHD®

Accurate liquid control made simple

EMHD controls liquid application rates using an electromagnetic flow meter. This opens up your options for a wider range of liquid products. Use the liquid product you want with the accuracy you need with EMHD.

FlowSense™

Measure row-by-row fertilizer rates

Current fertilizer flow meters tell you if fertilizer is flowing, not the rate that is being applied on each row. FlowSense allows you to measure the rate of fertilizer you are applying on each row of your planter or sidedress bar, to make you aware of any row-to-row variability that is occurring so that you can be confident in your application rate.

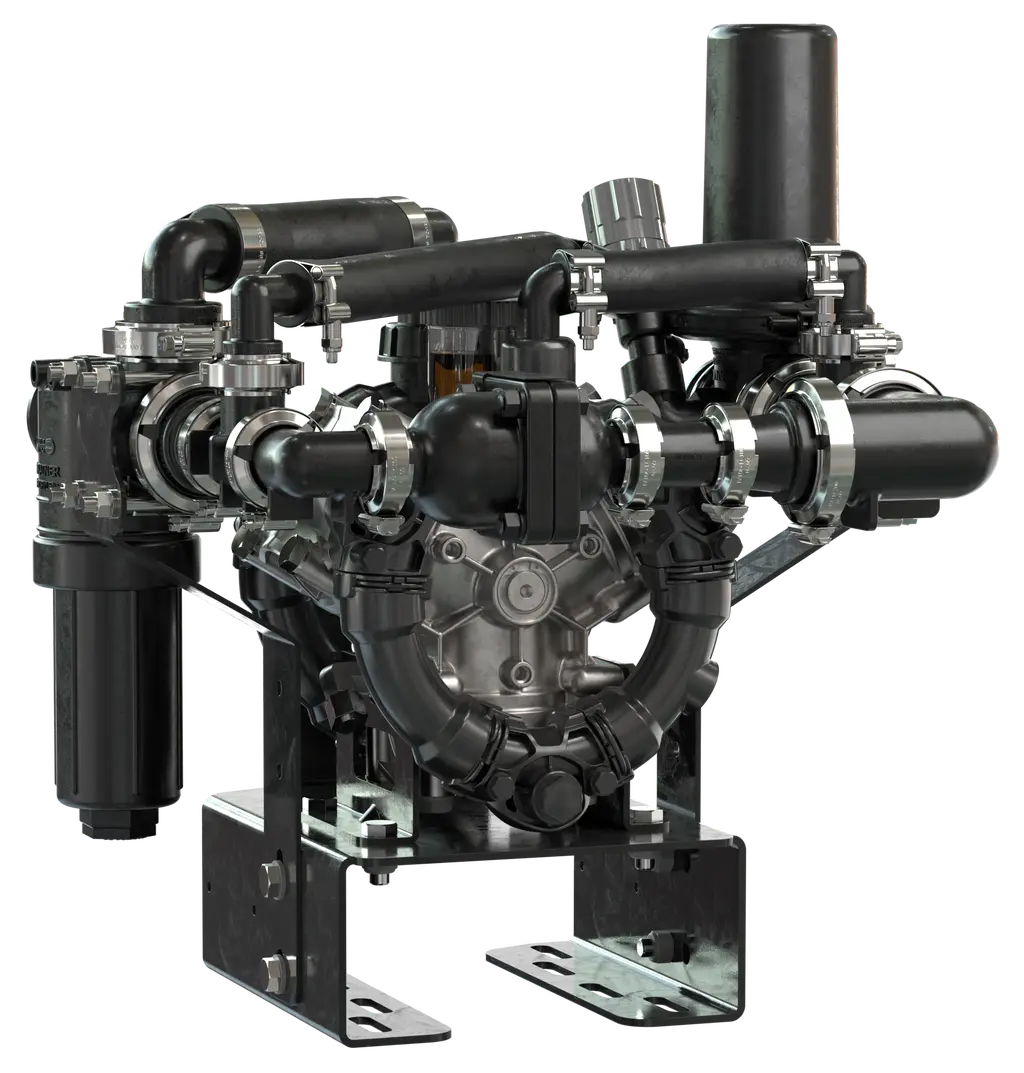

Pump Stack

Liquid fertilizer pump

Selecting the correct liquid fertilizer pump for your application technology and fertility program rates can be difficult. Precision Planting Pump Stack makes it easy to pair up your application technology with your fertility rates, and is designed to work with Precision Planting’s Fertility System or other rate controllers so that you can easily design a liquid fertility system.

DrySet Micro™

Accurate application of granular products

Easily switch between granular products with auger-based metering that allows for a variety of rates and products to be applied accurately and efficiently.

Rate Controller

Easily adjust applied rates on the go

Adjusting your liquid or granular product rates should be simple. With Precision Planting's RateController, you can easily adjust applied rates and compensate for speed changes on the go.

vApplyHD®

Accurate liquid control made simple

Farmers today experience up to 30% variability in the rate applied to each row with liquid control systems. vApplyHD allows you to get the correct rate of liquid fertilizer to every plant in your field, ensuring your plants never starve, so that your fertilizer ROI is maximized.

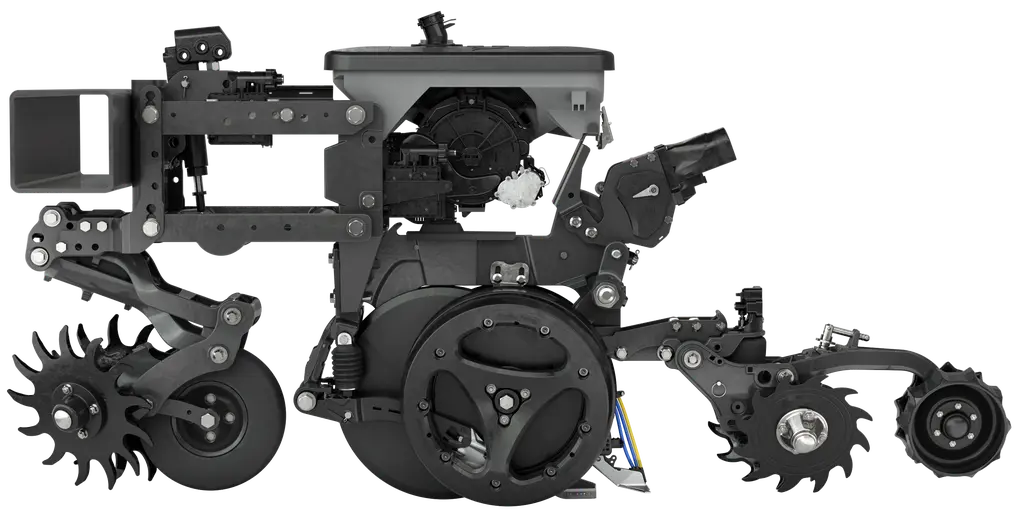

CornerStone

CornerStone®, from Precision Planting, is a fully custom, factory-built planting system with integrated Precision Planting hardware. Gain unmatched planting performance through ease of in-field use, simple adjustments for changing planting conditions, and best-in-class durability and serviceability. CornerStone's design is optimized for performance, simple adjustment, ease of in-field use, maintenance, and wear.